Equipment for the production of silicate boards

Calcium silicate board (English: calcium silicate) is made of loose short fiber such as inorganic mineral fiber or cellulose fiber as the reinforcing material, and calcium silicate material as the main cementing material. After pulping, shaping and saturated steam at high temperature and pressure, the curing reaction is accelerated to form a calcium silicate gel sheet. It is a new type of construction and industrial board with excellent performance, flame retardant, moisture-proof, sound-proof, insect-proof and good strength. It is an ideal decorative board for suspended ceilings and partition walls.

places of use

Commercial buildings, entertainment venues, shopping malls, hotels and industrial buildings; factories, warehouses and residential buildings; repair and reconstruction of new residential buildings, public places; Hospitals, theaters and railway stations.

Calcium silicate board - industrial panels such as walls, suspended ceilings, floors, furniture, road soundproofing, sound-absorbing barriers, ship compartments and air ducts, as well as sound-absorbing walls, sound-absorbing ceilings, bay walls, composite wall Are included. Panel, etc... area. Calcium silicate boards have good thermal insulation effect, can achieve 50% energy savings of new buildings, and are an integral part of modern wall building materials.

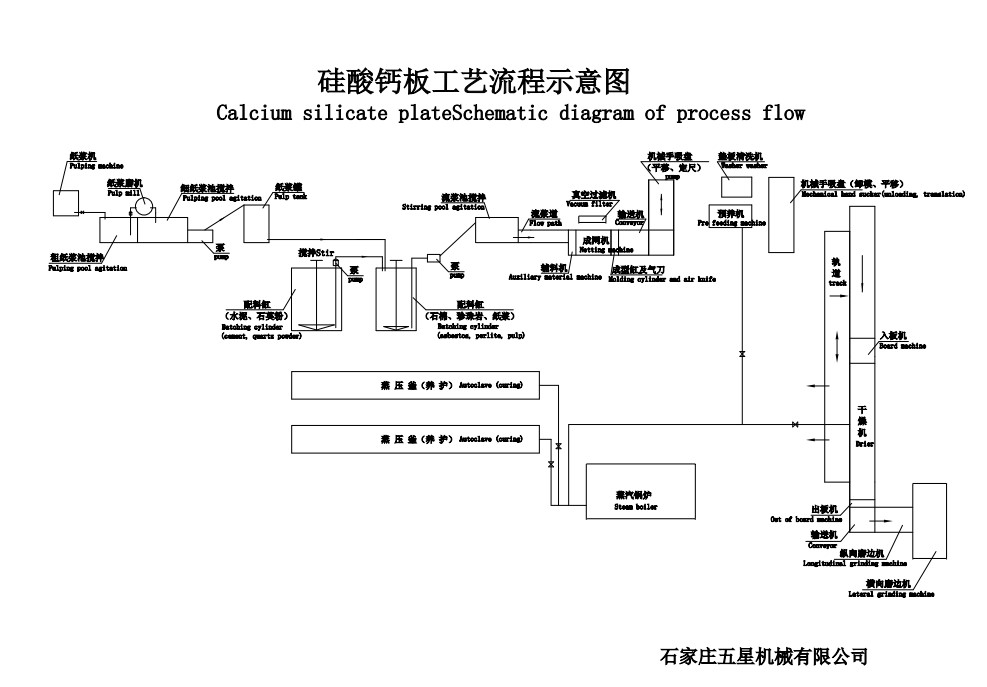

manufacturing process

folding raw material

(1) Silica material: quartz powder, diatomaceous earth, fly ash, etc.

(2) Lime material: slaked lime powder, cement, calcium carbide solution, etc.

(3) Reinforcing fiber: wood-paper fiber, wollastonite, cotton fiber, etc.

(4) Main material and formula: Silicon powder + Calcium powder + Natural wood fiber.

folding production method

There are molding method, copy method and flow suspension method. A common method is usually the extrusion method. After the raw material is fully mixed according to the design proportion, it is extruded and molded by a roller machine and molded at high temperature. The length is 2440mm, the width is 1220mm, and the normal thickness is 4-30mm.

Calcium silicate board is manufactured on the basis of lime material, silicon-containing material and reinforcing fiber (including asbestos or non-asbestos fiber) as the main raw material, and provided with various auxiliary materials. Fiber-reinforced calcium silicate board is formed and cured in an autoclave, and then surface ground and edge-finished to produce a finished board:

tank cleaning

mixture

Loose

recycle mixer

ladle tank for liquid masses

three chamber device, hydraulic head

spare disk

Inclined and Flat Welding Machine

Three-position hydraulic vacuum stacker for demolition

cutting machine

As a new type of environmentally friendly building material, calcium silicate board not only performs the functions of traditional gypsum board, but also has the advantages of excellent fire resistance performance, moisture resistance and long service life. It is widely used in building roofing, industrial and commercial engineering partition wall, home decoration, furniture paneling, billboard paneling, ship partition, warehouse shed board, floor and wall panel. Manufactured from high quality cement, reinforced with natural fibers and processed using advanced manufacturing techniques including moulding, compression and high temperature steam curing. This is a new type of construction with excellent characteristics for industrial use. Flame-retardant, moisture-proof, sound-proof, insect-proof and durable products; Ideal decorative board for suspended ceilings and partitions.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!