Drywall Production Equipment

Drywall production line is a special equipment for the production of new decorative materials at present, the main workflow includes:

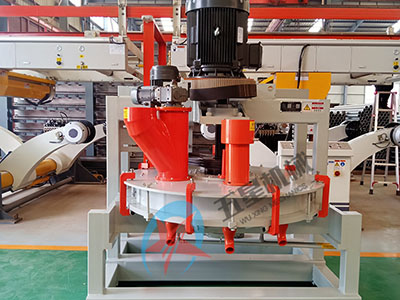

1. Add gypsum, water and various additives to the mixer with automatic dosing and automatic feeding system, mix and stir to form gypsum slurry, and sprinkle evenly

on protective paper that keeps on moving

2. With continuous advance, after vibration, the slurry is gradually evenly distributed, and then enters the extrusion molding machine to mix with the protective paper at the top and bottom, and the slurry is completely The upper and lower are covered with protective paper through extrusion, and extruded into a continuous cellulose gypsum board

3. The slab gradually formed a wet hard drywall through molding, natural curing and automatic cutting during the operation of the molding line. The wet board is formed by a CNC system and quickly enters the drying process through rollers, belts. and fold.

4. The board is strictly controlled in each temperature zone of the drying chamber, and hot air of different temperature is blown out, the moisture of the wet board is evaporated, the starch reaction board and the protective paper, and dried What binds drywall is glued. is removed from the drying room

5. Then turn the board and sheet over again (right side up) and cut the board with a cut-to-length saw to the specified size of the finished board.

6. Finally, it is transported to the automatic head and automatic palletizing, and then sent to the finished product warehouse by forklift.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!