Extruded cardboard

Intelligent DCS Control System

Capture and optimize big data from management records and operations. Receive real-time information from alarm records to maintenance records, and provide remote diagnosis and remote maintenance based on real-time information. DCS intelligent control system will help you scientifically manage the production and maintenance of equipment. Powerful industrial computers ushered in the era of big data for XPS creation.

Turnkey Projects - The Best Solution

For XPS project, quality production equipment is only the first step towards success. Our professional team not only provides comprehensive equipment, but also provides a wide range of technical services. Including workshop design consultation, warehouse logistics management, production formula management, equipment operation training and equipment maintenance training. We have our own talent pool ready to provide you with comprehensive professional services. We supply the equipments on turnkey basis.

Original XPS Board Process Path

Mixing → stirring → feeding → plasticizing extrusion foaming agent injection → low temperature extrusion → shaping → positive pressure molding → draft → cooling → cutting → (granulation and waste edge extrusion) → finished product

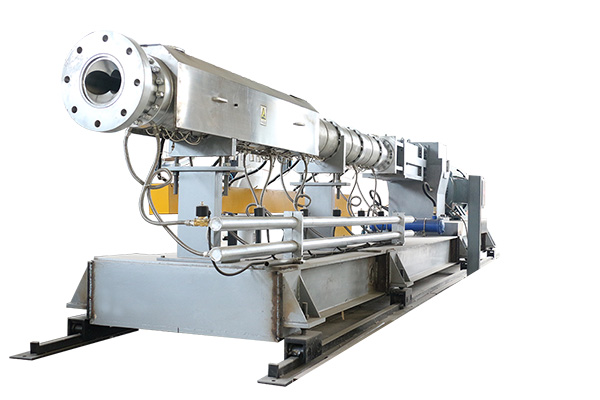

The general extruded board production line is divided into four parts: feeding and mixing unit, primary extrusion unit, secondary extrusion foaming unit and forming cutting unit.

1. The polystyrene resin, catalytic agent, flame retardant, etc. enter the first stage plastic extruder through the feeder;

2. After complete plasticization, a foaming agent (environmentally friendly foaming agent based on freon, gas, as well as carbon dioxide) is introduced into the extruder. The blowing agent is thoroughly mixed and cooled with the other raw materials in the second stage extruder;

3. After extrusion, the pressure is quickly released and the plastic-coated blowing agent rapidly forms closed cells. Under the action of cells, polystyrene plastic forms a closed-cell foam panel.

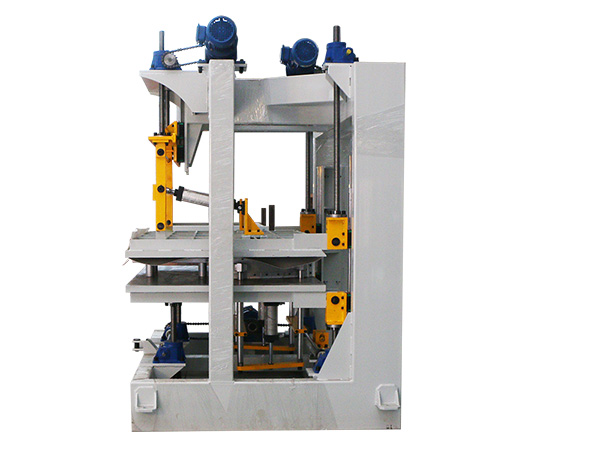

4. After the forming process, the plate is given the required thickness and width, and then it is cut.

5. Auxiliary equipment includes Extruded Carton Surface Roughing Machine, Recycling Granulator, Edge Forming Machine, Crushing Machine, Automatic Packaging Machine, etc.

Appliance model and power

Sample | Productivity (24 hours) | surface area, m (length * width * height) | Transformer |

TDS75--TDD160 | 380 Cubic meter | 70*15*8 | 300 KVA |

TDS75--TDD200 | 490 Cubic meter | 90*15*8 | 400 KVA |

TDS85--TDD250 | 600 Cubic meter | 110*15*8 | 500 KVA |

TDS95--TDD300 | 800 Cubic meter | 140*15*8 | 600 KVA |

TDS110--TDD300 | 1000 Cubic meter | 150*15*8 | 650 KVA |

TDS135--TDD400 | 1300 Cubic meter | 170*20*8 | 800 KVA |

TDS135--TDD500 | 2000 Cubic meter | 220*20*8 | 1200 KVA |

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!